Sheet Metal

Sheet Metal services

Sheet metal bending is a versatile, fast, and economical process for creating durable metal parts with complex geometries and tight tolerances. The process of forming parts from a metal sheet by punching, cutting, stamping, and bending. We have a team of professional sheet metal workers who can offer fast services and stable quality.

|

|

Manufacturing Process

- Produced by rolling metal slabs in hot or cold conditions

- Hot-rolled sheets (thicker, rough surface)

- Cold-rolled sheets (thinner, smooth surface finish)

Common Materials

- Steel (carbon steel, stainless steel)

- Aluminum (various alloys)

- Copper

- Brass

- Titanium (specialty applications)

Advantages of Sheet Metal

- Lightweight – Strong yet low weight (e.g., aluminum, steel).

- Cost-Effective – Low material waste, efficient production.

- Durable – Resistant to wear, corrosion (with coatings).

- Versatile – Bendable, weldable, formable into complex shapes.

- Fast Production – Laser cutting, stamping enable high-speed manufacturing.

- Recyclable – Eco-friendly (most metals are 100% recyclable).

- Common Uses: Automotive, aerospace, electronics, HVAC, construction.

Sheet Metal Cut

Sheet metal machine tool

Sheet metal machine tool

Spraying Workshop

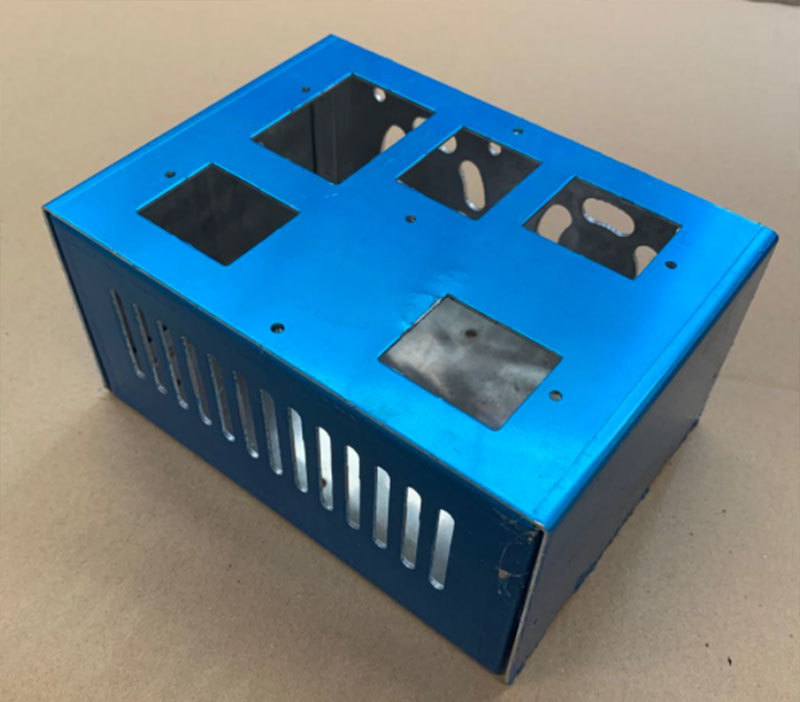

Chassis shell, sandblasted and anodized

Sheet metal plates

Sheet metal shell powder coating in color

Small batch shells