CNC Lathe Turning

CNC Lathe Turning services

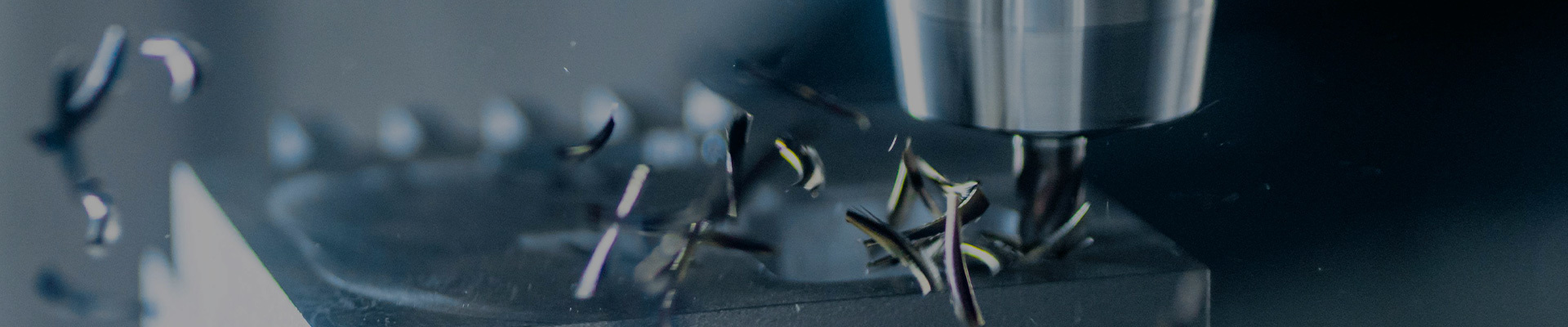

·A CNC Lathe is a precision machining tool that rotates a workpiece while a stationary cutting tool removes material to create cylindrical parts. It is widely used in manufacturing for producing high-accuracy components such as shafts, bushings, and threaded parts.

|

|

Why Choose CNC Lathe

- Ideal for: High-precision round parts, threaded components, or fast batch production.

- Avoid when: Parts require complex 3D features (use 5-axis milling instead).

- Lower per-unit cost than CNC milling for axisymmetric designs.

- Auto-Lathe machines for producing the precision turned parts,tolerance will be hold +/-0.01mm.

- The Maximum swing diameter of work over bed: Φ500mm, and the maximum turning length is 1000 mm.

Advantages of CNC Lathe Turning

- High Precision – Sub-micron accuracy (±0.005mm or better).

- Consistency – Identical parts in large batches.

- High Efficiency – Fast cutting, auto tool change, reduced cycle time.

- Complex Shapes – Threads, contours, and 3D profiles easily machined.

- Automation – 24/7 unmanned production with robotics.

- Flexibility – Quick program change for different parts.

- Lower Labor Cost – Less skilled operator dependency.

- Safer & Cleaner – Enclosed design reduces hazards.

CNC Lathe Turning

CNC Lathe Turning

CNC Lathe Turning

CNC Lathe Turning

Representative lathe parts

Representative lathe parts

Representative lathe parts

Small batch parts