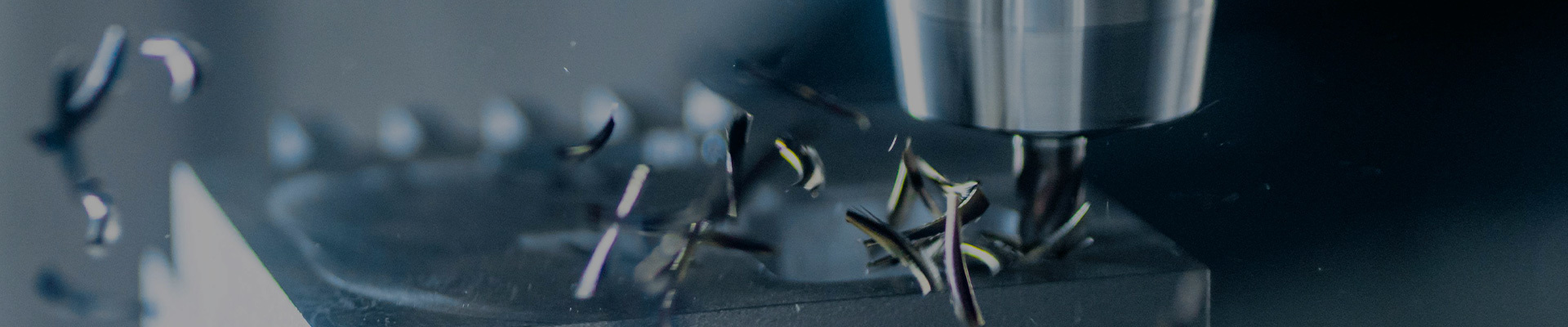

3-4-5 Axis CNC

CNC Milling services

·CNC machining is an efficient, precise, and flexible manufacturing method suitable for prototyping, small batch production, processing of plastic and metal parts with complex shapes. It can provide higher precision than injection molding / die-casting molds or 3D printing. For prototyping or small batch production, CNC machining does not require the production of expensive molds.

·Meanwhile, CNC machining can handle a wider range of plastic and metal materials, providing designers with more choices. The elective materials for Metal can be Aluminum, Brass, Copper, SteeI, lron, Magnesium, Zinc, etc. For Plastics can be ABS, PC, PMMA (Acrylic), PA (Nylon), PA+GF, PP, PE, Pu, PS, POM, PVC, Bakelite, Chemical, Solid Wood, etc.

|

|

Types of CNC Mills - Based on Axis Configuration

3-Axis CNC Mill

- Moves in X,Y,Z (left-right, forward-backward, up-down).

- Most common for simple parts (e.g., flat surfaces, pockets, holes).

- Example: Benchtop CNC mills, vertical machining centers ( VMCs).

4-Axis CNC Mill

- ·Adds a rotary axis (A-axis) for indexing or continuous rotation.

- ·Used for machining complex profiles (e.g., camshafts, cylindrical parts).

5-Axis CNC Mill

- Adds two rotary axes (A & B & C) for full multi-sided machining.

- Can machine complex geometries in a single setup. (e.g., aerospace blades, impellers).

-

Types:

Trunnion-style (rotary table tilts)

Swivel-head (spindle tilts).

|

|

How a CNC Mill Works

Step 1: CAD Design

- A 3D model is created in CAD software (e.g., SolidWorks, Fusion 360).

Step 2. CAM Programming

- CAM software (e.g., Mastercam, Fusion 360 CAM) generates toolpaths and G-code.

- Defines: Cutting tools, Feed rate, Spindle speed (RPM), Depth of cut.

Step 3. Machine Setup

- Workpiece Fixturing - Clamped to the table (vise, vacuum, custom fixtures).

- Tool Loading - Tools are installed in the ATC.

- Work Zero Setting - Using edge finders, probes, or manual touch-off.

Step 4. Machining Execution

- The CNC controller reads G-code and moves the spindle along programmed paths.

- Common operations: Face Milling, Pocketing, Drilling & Tapping, Contouring.

Step 5. Post-Processing (If Needed)

- Deburring, polishing, anodizing, or inspection ( CMM, micrometers).

|

|

Advantages of CNC Milling

- High Precision (±0.001” or better).

- Repeatability (Identical parts in mass production).

- Complex Geometries (5-axis for organic shapes).

- Automation (Light-out machining possible).

- Material Versatility (Metals, plastics, composites).

Polyhedral parts machined via 5 axis CNC

Polyhedral parts machined via 5 axis CNC

Polyhedral parts machined via 5 axis CNC

Polyhedral parts machined via 5 axis CNC