ABOUT US

Bolynn Rapid Model Limited

Bolynn Rapid Model Limited was founded in 2017 with the mission of bringing product design engineers’ idea into reality in a timely fashion. We bring decades of experience in rapid prototyping and product design. We aspire to be one of your strategic partners in feasibility study, development, and even volume manufacturing.

We look forward to hearing from you on your next project.

10+

YEARS OF RICH EXPERIENCE

100%

PRODUCTS INSPECTION

99%

QUALIFIED RATE

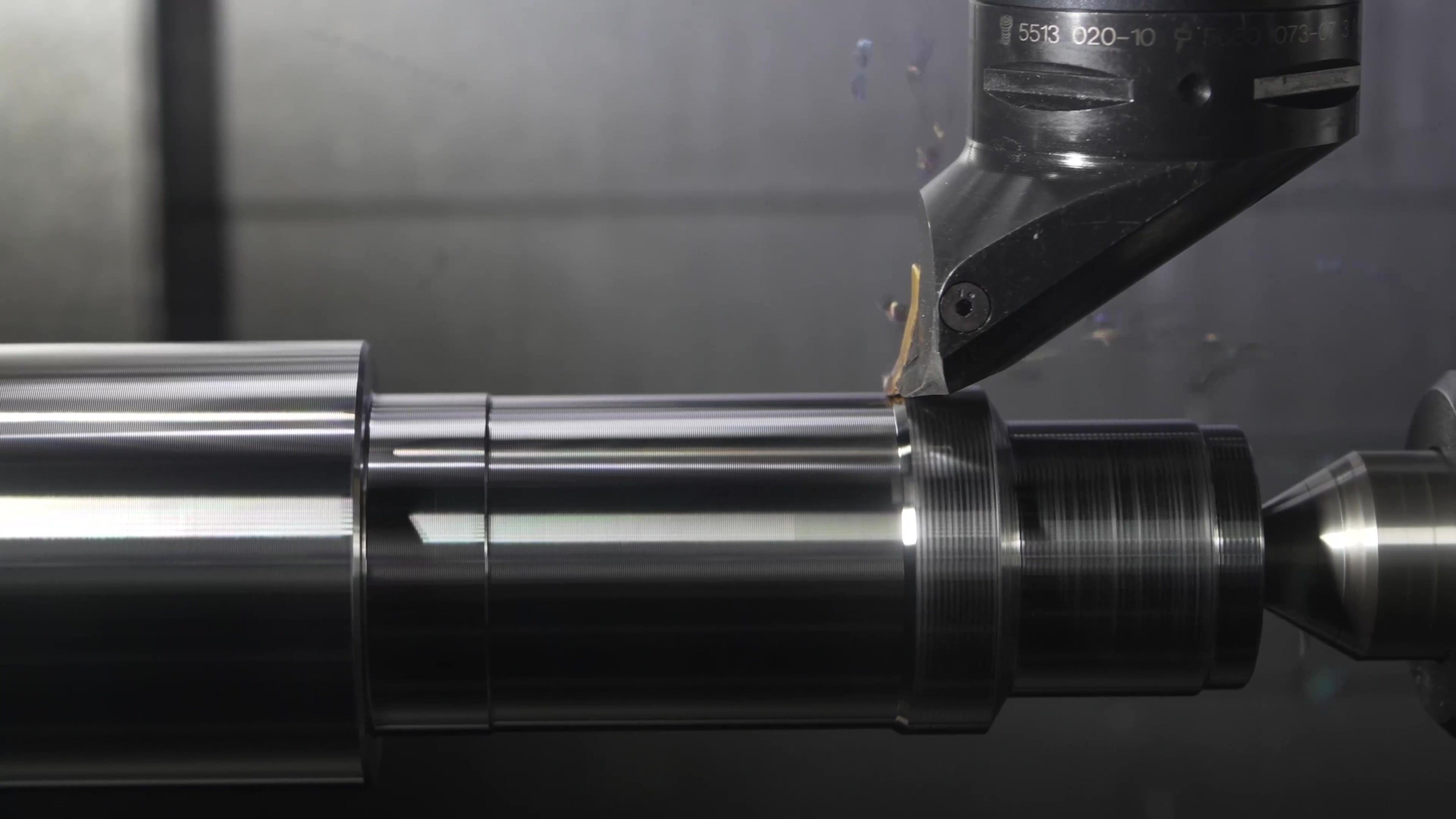

0.01MM

HIGH PRECISE TOLERANCE

3-5D

FAST DELIVERY TIME

1~1000+PCS

MOQ

CAPABILITIES

BUSINESS SCOPE

WHY CHOOSE US

Want to transform your ideas into reality swiftly, accurately, and economically? Welcome to contact Bolynn!

Original Factory Price

Fast manufacturing lead time

High precision machining, high-quality service

Comprehensive processing methods

Trusted long-term supplier

A comprehensive after-sales service system

BLOG