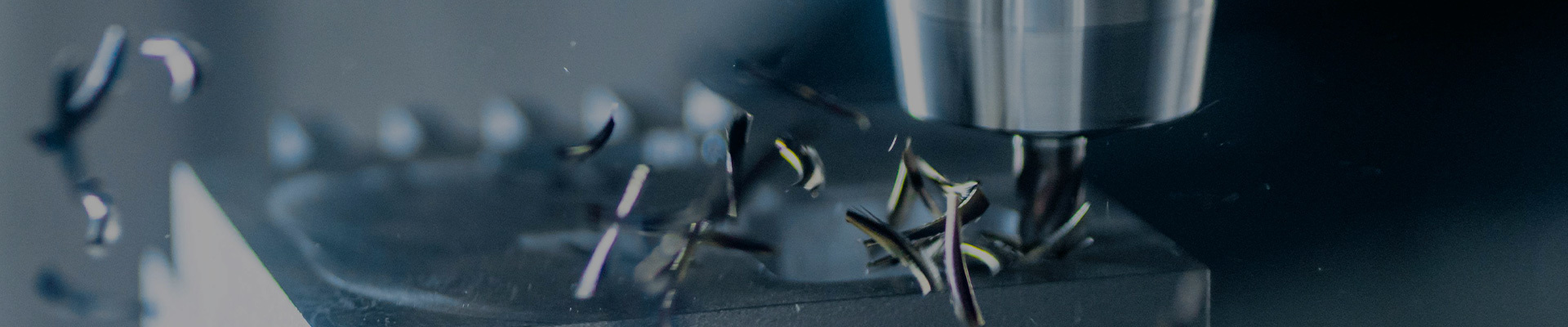

5 axis CNC machining

5-axis machining can cut chips on multiples sides of a part simultaneously in one setup. High precision, stable quality, cnc devices pulse is 0.001mm, precision could be achieved 0.1um; The machining is well-adapted with good flexibility.

5-axis machining is ideal for producing complex work pieces. The industries include: 360 degree rotation ball, embossements, medical components, worm and gear, generator rotor,die and mold.

CNC machining is an efficient, precise, and flexible manufacturing method suitable for prototyping, small batch production, and processing of plastic and metal parts with complex shapes.

CNC machining can provide higher precision than injection molding/die-casting molds or 3D printing. For prototyping or small batch production, CNC machining does not require the production of expensive molds.

It is designed flexibly, designers only need a pre designed CAD file to start processing directly from blank sheets or bars. During the production process, the engineering team can easily modify the design without incurring excessive additional costs when upgrading parts.

Meanwhile, CNC machining can handle a wider range of plastic and metal materials, providing designers with more choices.

The elective materials for Metal can be Aluminum, Brass, Copper, SteeI, lron, Magnesium, Zinc, etc

Plastics are ABS, PC, PMMA (Acrylic), PA (Nylon), PA+GF, PP, PE, Pu, PS, POM, PVC, Bakelite, Chemical, Solid Wood, etc

Polyhedral parts machined via 5 axis CNC

Polyhedral parts machined via 5 axis CNC

Polyhedral parts machined via 5 axis CNC

Polyhedral parts machined via 5 axis CNC

Polyhedral parts machined via 5 axis CNC