In the fast - paced world of product development, vacuum casting prototyping has emerged as a crucial and innovative technique.Vacuum casting prototyping offers numerous advantages for manufacturers and designers alike. This process is highly advanced, allowing for the creation of high - quality prototypes with exceptional precision. Manufacturers in various industries are increasingly turning to vacuum casting prototyping to accelerate their product development cycles.

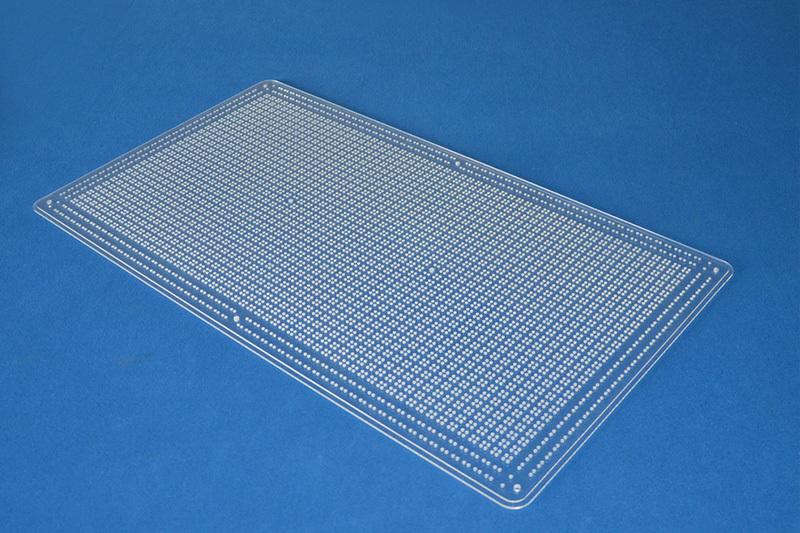

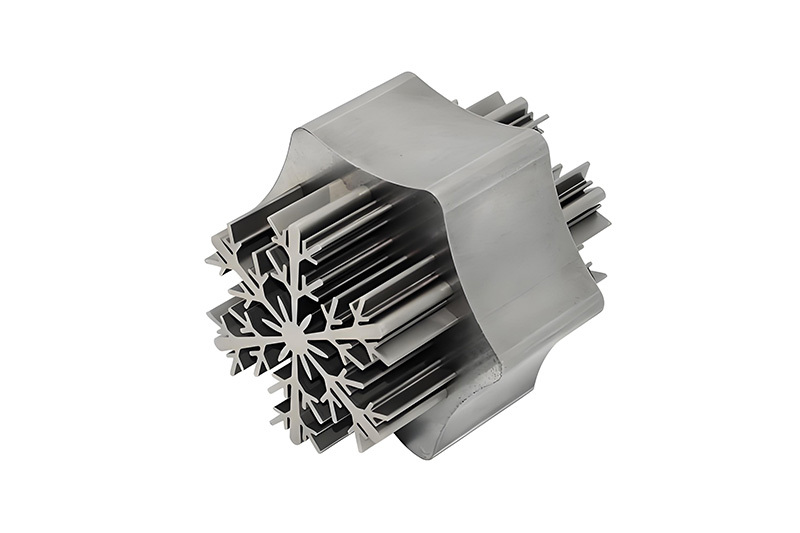

One of the key features of vacuum casting prototyping is its ability to replicate the final product's characteristics with great accuracy. It can produce prototypes with smooth surfaces, fine details, and accurate dimensions. This is especially important for industries such as automotive, consumer electronics, and medical devices, where the fit and finish of a product are critical.

The durability of prototypes created through vacuum casting is also remarkable. They can withstand a reasonable amount of handling and testing, enabling engineers and designers to evaluate the product's functionality and performance more effectively. This helps in identifying potential design flaws early in the development process, saving both time and cost.

Many leading manufacturers around the world are now partnering with suppliers that specialize in vacuum casting prototyping. These suppliers often have a team of highly skilled technicians and use the newest and best - quality materials. Their advanced equipment and techniques ensure that the vacuum casting process is carried out with utmost precision.

In addition, the cost - effectiveness of vacuum casting prototyping cannot be overlooked. Compared to other prototyping methods, it offers a more affordable solution without compromising on quality. This makes it accessible to both large - scale companies and small - to - medium - sized enterprises.

Chinese manufacturers are also making their mark in the vacuum casting prototyping field. With their expertise in manufacturing and cost - control, they are able to provide vacuum casting prototyping services at competitive prices. These Chinese suppliers often offer customization options, allowing clients to tailor the prototypes to their specific needs.

Furthermore, some companies provide comprehensive design services in conjunction with vacuum casting prototyping. Their creative teams can work with clients to develop concept designs and turn them into tangible prototypes. This end - to - end solution approach is highly valued by product developers who are looking for a seamless experience from idea to prototype.

In conclusion, vacuum casting prototyping is a game - changer in the product development landscape. Its combination of precision, durability, cost - effectiveness, and customization options make it an ideal choice for companies looking to bring their innovative ideas to life quickly and efficiently. Whether it's for a new consumer gadget or a complex industrial component, vacuum casting prototyping is set to play an increasingly important role in the future of manufacturing.

Keywords

Line Cutting

Line Cutting,vacuum casting prototyping

Contact Us

Classification